Harnessing the Global Offshore Wind Boom

Around 100GW of offshore wind capacity is expected to be deployed globally by 2030. Whilst Europe has very much been at the forefront of this energy revolution, turbines will be deployed in ever deeper waters, farther from shore across the globe from Asia to the Americas.

This offshore wind boom is underpinned by a dramatic reduction in the Levelized Cost of Energy (LCOE); scale is a key driver – next-generation turbines will stand up to 500m tall and must be able to cope with some of the harshest conditions on the planet for over 25 years.

Harnessing the Global Offshore Wind Boom

Around 100GW of offshore wind capacity is expected to be deployed globally by 2030. Whilst Europe has very much been at the forefront of this energy revolution, turbines will be deployed in ever deeper waters, farther from shore across the globe from Asia to the Americas.

This offshore wind boom is underpinned by a dramatic reduction in the Levelized Cost of Energy (LCOE); scale is a key driver – next-generation turbines will stand up to 500m tall and must be able to cope with some of the harshest conditions on the planet for over 25 years.

Understanding the Needs of Our Customers

At Windhoist, we understand that offshore wind developers seek supply partners that can positively contribute to the offshore wind value proposition by stimulating Skills, Competition and Innovation.

Skills - As an independent GWO accredited training provider, we are improving skills across the sector. We

seek to create a truly international team and develop our people internally the Windhoist way; the

fact that we have the longest average length of service in the sector is testament to our

development credentialsCompetition - we offer our customers the most compelling commercial propositions on the market customised to

individual needsInnovation is in our DNA; we propose progressive solutions to our customers across the technical,

commercial and service provision spectrum

Understanding the Needs of Our Customers

At Windhoist, we understand that offshore wind developers seek supply partners that can positively contribute to the offshore wind value proposition by stimulating Skills, Competition and Innovation.

Skills - As an independent GWO accredited training provider, we are improving skills across the sector. We

seek to create a truly international team and develop our people internally the Windhoist way; the

fact that we have the longest average length of service in the sector is testament to our

development credentialsCompetition - we offer our customers the most compelling commercial propositions on the market customised to

individual needsInnovation is in our DNA; we propose progressive solutions to our customers across the technical,

commercial and service provision spectrum

Our Offshore Wind Proposition

Windhoist is the industry’s leading one-stop-shop provider of offshore wind turbine installation and logistical services. With a wide spectrum of capabilities, our model reduces interface risk for our customers.

Our Offshore Wind Proposition

Windhoist is the industry’s leading one-stop-shop provider of offshore wind turbine installation and logistical services. With a wide spectrum of capabilities, our model reduces interface risk for our customers.

Plant equipment

Turbine installation, commissioning, maintenance and decommissioning

World-class engineering and operational excellence

- The most advanced suite of heavy lift craneage on the market, from 25t to 1,200t

- Full port logistical support package capabilities, from haulage to self-propelled modular transporters

- Highly-skilled, multi-disciplinary site teams with a wealth of experience in handling all types of turbine components

- Full back office project management capabilities

- Full suite of site survey, risk assessment, method statement and real-time scheduling and reporting capabilities

- Expert process flow and modelling capabilities via the latest computer-aided design and drafting software

Plant equipment

- The most advanced suite of heavy lift craneage on the market, from 25t to 1,200t

- Full port logistical support package capabilities, from haulage to self-propelled modular transporters

Turbine installation, commissioning, maintenance and decommissioning

- Highly-skilled, multi-disciplinary site teams with a wealth of experience in handling all types of turbine components

- Full back office project management capabilities

World-class engineering and operational excellence

- Full suite of site survey, risk assessment, method statement and real-time scheduling and reporting capabilities

- Expert process flow and modelling capabilities via the latest computer-aided design and drafting software

Windhoist Offshore

Delivering Customised Solutions

Having delivered more that 11GW of capacity since 2005, we have invested in a number of key competencies specifically to service the needs of the offshore wind sector. Our modular concept allows us to serve our customers globally whilst maintaining the same high level of quality, HSE and schedule adherence each and every time.

Having delivered more that 11GW of capacity since 2005, we have invested in a number of key competencies specifically to service the needs of the offshore wind sector. Our modular concept allows us to serve our customers globally whilst maintaining the same high level of quality, HSE and schedule adherence each and every time.

Typical Windhoist offshore wind capability spread:

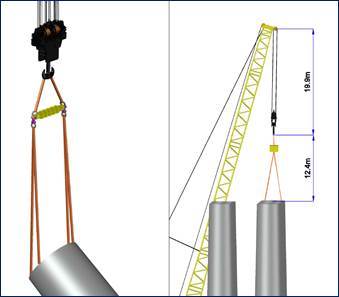

Main crane ~ LR1750/2 Crawler crane with the latest SX boom system

- 118m Main boom with L-head

- 42m Derrick mast

- 220t superstructure ballast

- 300t super-lift counterweight on Ballast wagon

- 95t car-body ballast

- 2m Wide tracks to reduce ground pressure loadings

Typical Windhoist offshore wind capability spread:

Main crane ~ LR1750/2 Crawler crane with the latest SX boom system

- 118m Main boom with L-head

- 42m Derrick mast

- 220t superstructure ballast

- 300t super-lift counterweight on Ballast wagon

- 95t car-body ballast

- 2m Wide tracks to reduce ground pressure loadings

Support and mobile cranes

LR1300 with longer boom used for extra height to stack blades onto the installation vessel

- 56m main boom

- 124t superstructure counterweight

- 57t car-body weight

- Most Onerous lift – Base tower tailing

- Tower – 80.2t

- Rigging weight – 3.4t

- Hook Block - 2.3t

- Total – 85.9t

- Capacity – 98.5t @ 14m Radius

- 87% Utilisation for towers

- Blade placement at 40m radius achievable

Support and mobile cranes

LR1300 with longer boom used for extra height to stack blades onto the installation vessel

- 56m main boom

- 124t superstructure counterweight

- 57t car-body weight

- Most Onerous lift – Base tower tailing

- Tower – 80.2t

- Rigging weight – 3.4t

- Hook Block - 2.3t

- Total – 85.9t

- Capacity – 98.5t @ 14m Radius

- 87% Utilisation for towers

- Blade placement at 40m radius achievable

Equipment

Our range of assembly tools is unsurpassed. Our assembly teams arrive on our customers’ site with a full suite of equipment via our modular support pod concept.

We carry a full stock of: certified hoists and slings, calibrated hydraulic torque tools, hand tools, bog mats, electrical equipment and PPE which is replenished on site via our central inventory hub

We customize our support pods to the specific needs of our customers.

Equipment

Our range of assembly tools is unsurpassed. Our assembly teams arrive on our customers’ site with a full suite of equipment via our modular support pod concept.

We carry a full stock of: certified hoists and slings, calibrated hydraulic torque tools, hand tools, bog mats, electrical equipment and PPE which is replenished on site via our central inventory hub

We customize our support pods to the specific needs of our customers.

Engineering & lift expertise

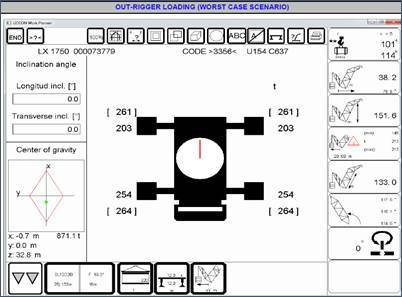

We have world-class systems modelling every aspect of construction and lifting.

It is standard practice for us to visit assembly sites prior to the start of each project in order that we can understand local conditions and propose truly customised and optimised solutions.

Engineering & lift expertise

- We have world-class systems modelling every aspect of construction and lifting

- It is standard practice for us to visit assembly sites prior to the start of each project in order that we can understand local conditions and propose truly customised and optimised solutions

Our track record in Offshore wind:

Our track record in Offshore wind:

The Worlds biggest Offshore Wind Farm Hornsea One

producing enough energy to power one million homes

Portside construction of 174 x 7MW turbines for the Hornsea One wind farm are fully underway as Windhoist have fully erected and populated 84 towers. The towers are now on their next journey as they are taken on vessels.

Check other projects we’ve worked on

- Customer:Samsung Location: Methil, Scotland

Portside construction and installation of 7MW demonstrator turbine

- Customer: Grupo Cobra Location: Dundee, Scotland

Portside construction of 2MW floating demonstrator turbine

- Customer: Siemens Location: Nigg, Scotland

Portside construction of 84 x 7MW turbines for the Beatrice wind farm

- Customer: Siemens Location: Hull, England

Portside construction of 174 x 7MW turbines for the Hornsea One wind farm

The Worlds biggest Offshore Wind Farm Hornsea One

producing enough energy to power one million homes

Portside construction of 174 x 7MW turbines for the Hornsea One wind farm are fully underway as Windhoist have fully erected and populated 84 towers. The towers are now on their next journey as they are taken on vessels.

Check other projects we’ve worked on

- Customer:Samsung Location: Methil, Scotland

Portside construction and installation of 7MW demonstrator turbine

- Customer: Grupo Cobra Location: Dundee, Scotland

Portside construction of 2MW floating demonstrator turbine

- Customer: Siemens Location: Nigg, Scotland

Portside construction of 84 x 7MW turbines for the Beatrice wind farm

- Customer: Siemens Location: Hull, England

Portside construction of 174 x 7MW turbines for the Hornsea One wind farm